: Shenzhen Lingyu e-commerce Co., LTD!

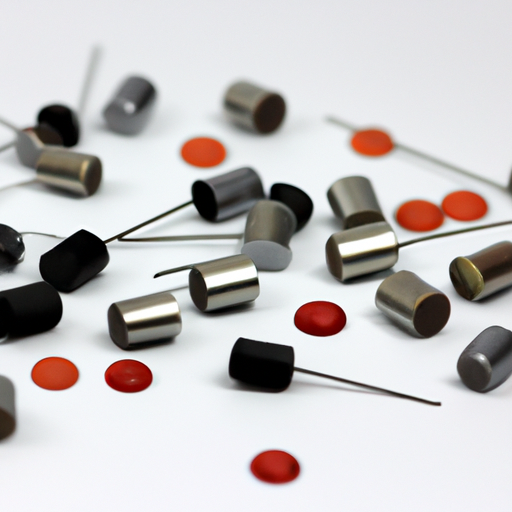

Polymer capacitors are a type of capacitor that uses a conductive polymer as the electrolyte instead of a liquid or gel electrolyte. This type of capacitor offers several advantages over traditional electrolytic capacitors, including lower ESR (equivalent series resistance), longer lifespan, and better stability over a wide range of temperatures. In recent years, there have been significant advancements in the manufacturing processes of polymer capacitors, leading to improved performance and reliability. In this article, we will explore some of the latest manufacturing processes used in the production of polymer capacitors.

In addition to using advanced materials, manufacturers are also employing innovative manufacturing processes to improve the performance of polymer capacitors. One such process is the use of thin film deposition techniques to create the electrodes of the capacitor. Thin film deposition involves depositing a thin layer of metal onto a substrate using techniques such as sputtering or evaporation. This process allows for precise control over the thickness and composition of the electrode, leading to improved performance and reliability of the capacitor.

Another important manufacturing process used in the production of polymer capacitors is the use of advanced packaging techniques. Packaging plays a crucial role in the performance and reliability of capacitors, as it protects the internal components from external factors such as moisture and temperature fluctuations. Manufacturers are now using advanced packaging materials such as epoxy resins and silicone gels to encapsulate the capacitor, providing a high level of protection against environmental factors.

Furthermore, manufacturers are also focusing on improving the assembly processes of polymer capacitors to ensure consistent quality and reliability. One such process is the use of automated assembly equipment, which allows for precise placement of components and reduces the risk of human error. Automated assembly equipment also enables manufacturers to increase production efficiency and reduce costs, leading to lower prices for consumers.

In addition to these advancements in manufacturing processes, manufacturers are also investing in research and development to further improve the performance of polymer capacitors. One area of research is the development of new polymer materials with enhanced conductivity and stability. Researchers are also exploring new electrode materials and designs to improve the performance of polymer capacitors even further.

Overall, the latest manufacturing processes in polymer capacitor production are focused on improving performance, reliability, and cost-effectiveness. By using advanced materials, innovative manufacturing techniques, and automated assembly processes, manufacturers are able to produce high-quality polymer capacitors that meet the demands of modern electronic devices. With ongoing research and development efforts, we can expect to see further advancements in polymer capacitor technology in the coming years.